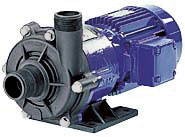

| Magnetic drive pumps: |

The patented pin-point contacting system gives the magnetic drive pumps dry-running capability

Process magnetic drive pumps MDH, MDH-F series

Catalog for Europe

Catalog for Europe

Catalog for Asia

Catalog for Asia

|

Dry running is possible with a pin-point contacting system

Up to one-hour of continuous dry running is possible due to the pin-point contacting system which minimizes the heat generation of the sliding parts during dry running. (Note) Dry running is possible with the carbon bearing type (D type only.) Excellent corrosion resistance The casings, impeller assembly and magnet capsule of MDH pump are made of polypropylene and those of MDH-F are made of fluororesin. Other wet-end parts are made of highly corrosion resistant materials such as carbon, ceramics and the like. The pumps can handle almost type of chemicals including acid and alkali. Excellent durability The resin parts for MDH are reinforced with glass fiber and MDH-F is reinforced with carbon fiber for the purpose of enhancing durability. In addition, sufficient consideration was given to the mechanical strength and the safety of the spindle. Simple structure The pump unit's simple structure consists of only a few parts. The assembly and disassembly procedures for maintenance purposes are very easy and simple. |

Specifications (50/60Hz)

| Model | MDH | MDH-F |

| Max. discharge capacity | 600 L/min | 500 L/min |

| Max. head | 29/31 m | 24/23 m |

| Main materials | GFRPP | CFRETFE |

| Required power range | 0.4 to 3.7 kW | 0.4 to 2.2 kW |

| Discharge bore | 40 mm | 40 mm |

| Liquid temp. range | 0 to 80 C deg. | 0 to 80 C deg. |

| Specific gravity limit | Up to approx. 2.0 (Please contact us for details.) |

Up to approx. 2.0 (Please contact us for details.) |

| Sealing method | Seal-less construction | Seal-less construction |

| Other Magnetic Drive Pumps : |

magnetic drive pumps

| Process pumps |

Self-priming pumps |

Small size pumps |

Direct drive pumps |

| MDE series MDM series MXM series MDF-L series AMP series MX, MX-F series MDH, MDH-F series |

SMX, SMX-F series | MD series MD-F series |

RD series |

NdFeB production line

NdFeB production line Vacuum Induction Melting Furnace

Vacuum Induction Melting Furnace