| Product Detail: |

Electrolyte

The electrolyte has been used by several big manufacturers in many well known brands of aluminum electrolytic capacitor. Our processesses advanced production process, etchnologies and equipments.

The leading products of our company includes SL-24, SL-15, SL-25, SL-12,K-16, JZ-1, SL-25A, SK-2, H160, M250, H250, H400, L521 and H450,etc.

With all kinds of sepcifications and exellent quality, our produts have reasonable price. Holding the principle of reciprocity and mutual benefit, we welcome your contac and presence and will offer you perfect service.

Description and Specification of Electrolyte:

|

|

|

|

Introduction and Characteristics of the Electrolyte.pdf

Introduction and Characteristics of the Electrolyte.pdf

Quality Sandard of Electrolyte:

1.Sodium  chlorides Formulation of chlorides titer:

chlorides Formulation of chlorides titer:

1.0.16g sodium chloride (500ºC-600ºC);

2.interpose the sodium chloride into 1000ML beaker, dilute to the mark;

2.Anhydrous sodium sulfate  sodium sulfate

sodium sulfate

- Prepare 0.148g anhydrous sodiumsulfate (105-110 ºC);

- Interpose the anhydrous sodium sulfate into 1000ML beaker, dilute to the mark.

3. Nitric acid solution with 25% chlorides CL Formulation Step:

- Prepare 200M+/-65% strong nitric acid;

- prepare 320ML ionized atom water;

- Decant 1 into 2, never reverse, and agitate;

4. 20g/L silver nitrate solution (2% silver nitrate AgNO3 solution) Formulation Step:

- Prepare 40ML silver nitrate solution, namely 50g/L (namely 5% silver nitrate solution)

- Prepare 60ML ionized atom water, and mix the solution 1 and 2;

5. Test criteria of electrolyte:

- The PH value of electrolyte be controlled between 6 and 7.5;

- CL-≤1PPM SO2- ≤5PPM Fe3+ ≤ 5PPM

Glacial acetic acid (acetic acid) in analytically pure;

6. 250g/L button panel solution ( namely 25% Bac1 solution) Formulation Step:

- Prepare 25g Bac1 analytically pure;

- Add ionized atom water to the 100ML mark and agitate;

- In general conditions, the water used in the test are ionized atom water in analytically pure or above if no clear indication of other requirements.

- Should use test tube to fetch solution in sediment tests, and the minimum volume of each fetch should be 0.05ML, normal temperature (15ºC-25 ºC)

7. Formulation of mother liquor:

Get 50g electrolyte using 100ml beaker with 0.1g precision: add 30ML 25% nitric acid solution add mix. Place in refrigerator for 2 hours until Ammonium Pentatborate and Ammonium Adipate subsid fully or separate by crystallization, filtrate with funnel. And then ge mother liquor A for use.

Requirement: CL-≤1PPM

Measure Step:

Fetch A10ML mother liequor iinto 50ML color comparison tube using straw, add 1ML 25% NITRIC ACID SOLUTION AND 1ml20g/L silver nitrate solution, dilute to 25L, shake up and wait 10 minutes, then compare with titer, and the turbidity should not greater than the titer.

Measure of sulfate

Requirement SO42- ≤5PPM

Measurement Step:

Inject A10ML mother liquor into 50ML test tube, add 1 ML glacial acetic acid and 1 ML barium chloride (250G/L), dilute to 25 ML and shake up, wait 10 minutes and compare with titer, the turbidity should not be greater than titer.

Titer: inject 50ML vitriol standard (0.0005MG SO42- /ML) into 100ML beaker, add 30ML 25% nitric acid solution and shake up, then get 10ML into 50ML color comparison tube as produre of mother liquor A10M1 in 1 and 2.

Measurement of iron ion

Requirement: Fe3+≤5PPM

Inject mother liquor A10ML into 50ml color comparison tube using straw (10ML), add 1ML4N vitriol, 4ML 25% thiocyanic acid solution, delute to 25 ML, abserve from top to bottom with a white substrate, and compare with titer, the redness should not be deeper than titer.

Titer: inject 50ML Fe3+ titer (0.0005MG Fe3+/ML) into beaker using pipette (25ML), add 30ML 25% mitric acid solution and shake up, then get 10ML into 50ML color comparison tube, and process as 310 ML mother liquor A in 1.

Notes: If electrolyte has solute with strong reducing property (such as hypo-potassium phosphite), when inspect chloride ion.

Guaranty for the material contained in our company’s products

The main constituent elecments of electrolyte we provide to your esceemed company include glycol, hexanedioic acid ammonium, mannitol do not include limited material as follows:

- Cadmium and Cadmium Compound;

- Polychlorinatod blphenyls

- Multi-bromine Biphenyl and Ethers Oxide Compound;

- Organic Stannum and its compound (Tributyl Yasuyoshyi/Tripnenyhin)

- Organic Bronmine and Organic Bromine Compound;

- Oxidixed Petholeum Wax.

All our electrolyte products meet Europe Standards

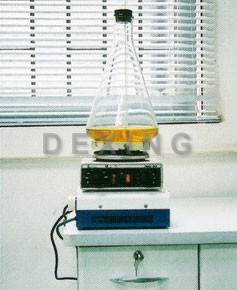

Instrument type: Taiwan Lunyang Company LY-20

Instrument setting:

1. electric current:20m step;

2.voltage: 600v step

Adoption of material:

1.spangle foil Area:2cm2

2.One 100ml beaker,two clips;

Testing method:

Measuring off 70-80ml electrolyte with beaker in 300C room temperature,notes:the Contract area between spangle foil and electronlyte is 2cm2.Cliping them respectively, and then turning on the power of instrucment.You must pay attention to the change of the spangle foil on the anode clip.When the voltage is high enough,the spangle foil on the anode clip will flash fire. And then the data indicated by the instument is the correct spark voltage of electrolyte.

In recent years,some companies heat up the electrolyte to 85% and then test it.In fact,there are no evident are difference between test at 30% and 85%,and the spark voltage will be higher about 20v(it’s my personal comparition,not the reference).

NdFeB production line

NdFeB production line Vacuum Induction Melting Furnace

Vacuum Induction Melting Furnace