| Product Catalog: |

Magnet Field Injection Machine

- DXCJ120M3V Magnetic Field Injection Machine

- DXBT-100 Magnetic Field Injection Machine

- DX-SERIES Magnetic Field Injection Machine

- Ceramic Injection Molding Machine

| Product Detail: |

DXBT-100 Magnetic Field Injection Machine

My company manufacturing the magnetic field Injection Molding Machine practical high quality RE, ferrite magnetic plastic products (same-sex and heterosexual), ceramics, such as injection molding powder alloy production, production of the products to achieve a variety of magnet orientation, such as: axial, radial, composite orientation. Electrical equipment used LCD computer control, a high degree of automation; The magnetic field generated magnetic field generator of more than 30000-turn, produce high-performance products; Electrical components are used hydraulic original Japanese imports, performance is stable and reliable; Screw Machine extinguishers were sprayed by dual metal or high wear-resistant alloys, it TING fate has been greatly increased.

My company manufacturing the magnetic field Injection Molding Machine practical high quality RE, ferrite magnetic plastic products (same-sex and heterosexual), ceramics, such as injection molding powder alloy production, production of the products to achieve a variety of magnet orientation, such as: axial, radial, composite orientation. Electrical equipment used LCD computer control, a high degree of automation; The magnetic field generated magnetic field generator of more than 30000-turn, produce high-performance products; Electrical components are used hydraulic original Japanese imports, performance is stable and reliable; Screw Machine extinguishers were sprayed by dual metal or high wear-resistant alloys, it TING fate has been greatly increased.

Technical Data For "BT"series Injection Molding Machine For Plastic Bonded Magnet:

DESCRIPTION |

UNIT |

BT80 |

BT100 |

BT120 |

SCREW? DIAMETER |

mm | 32 | 40 | 45 |

SCREW? L/D? RATIO |

L/D | 20 | 215 | 20..6 |

| MAX. THEORETICAI INJECTION CAPACITY | cm3 | 92 | 1885 | 262 |

| SHOT WEIGHT(PS) | g | 250 | 510 | 680 |

| MAX. INJECTION PRESSURE | kg/cm2 | 1640 | 1560 | 1548 |

| MAX. THEORETICAL INJECTION RATE(PS) | cm3/sec | 64 | 78 | 100 |

| MAX. PLASTICIZING CAPACITY(PS) | kg/h | 34 | 64 | 82 |

| SREW STROKE | mm | 245 | 295 | 295 |

| SCREW TORQUE | kg.m | 35 | 62 | 65 |

| SCREW SPEED RANGE | r.p.m. | 10-210 | 10-220 | 10-240 |

| NOZZLE FORCE/STROKE | ton/mm | 4/200 | 4/250 | 5.65/300 |

| HEATING CAPACITY | kw | 6.5 | 7 | 10 |

| QUANTITY OF HEATING ZONE | pc(s) | 3+N | 3+N | 3+N |

| MAX. CLAMPING FORCE | ton | 80 | 100 | 120 |

| MAX. OPENGING STROKE | mm | 300 | 320 | 335 |

| MIN-MAX MOULD THICKNESS | mm | 100-300 | 135-350 | 150-350 |

| MAX. DISTANCE BETWEEN MOULD PLATENS | mm | 600 | 670 | 685 |

| SPACE BETWEEN THE BARS(VXH) | mm | 320x320 | 355x355 | 355x355 |

| MOULD PLATEN SIZE(WXH) | mm | 470x470 | 515x515 | 530x530 |

| EJECTOR FORCE/STROKE | ton/mm | 2.2/60 | 2/80 | 2.75/90 |

| EJECTOR QUANTITY | pc(s) | 1or5 | 1or5 | 1or5 |

| PUMP MOTOR POWER | kw | 7.5 | 11 | 11 |

| PUMP Q. MAX | L/min | 45 | 55 | 65 |

| MACHINE SIZE(LXWXH) | m | 4.6x0.85x1.5 | 4.8x1x1.6 | 4.9x1.1x1.7 |

| MACHINE NET WEIGHT | ton | 2.5 | 3.4 | 3.5 |

| MAGNETIZING | A | 0-170 | 0-180 | 0-200 |

| DEMAGNETING | A | 0-80 | 0-80 | 0-80 |

| MAGNETIC FIELD CAPACITY | 10k Ampere.turn | 25 | 28 | 32 |

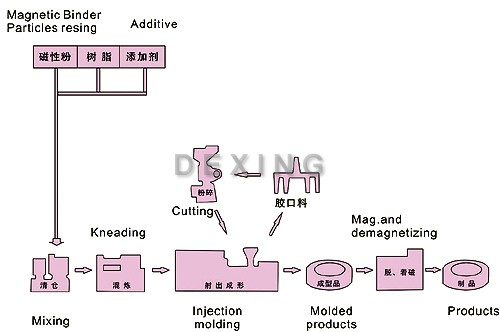

NdFeB production line

NdFeB production line Vacuum Induction Melting Furnace

Vacuum Induction Melting Furnace