| Product Detail: |

Cold Isostatic Press

| Product Detail: |

DX300-400 Integrated Cold Isostatic Press

DX Series Experimental Integrated CIP

1.Features

Advantages: Intuitive touch interface with full-color graphics. Setting and control of high-precision pressure curve. The whole pressure cycle data recordable and traceable, which makes it possible to compare the difference of deforming effects of materials under different isostatic pressing processes. Accurate control of servo system, quiet and smooth operation, lower energy consumption than traditional oil pump generator system. Convenient automatic lifting and charging, without any auxiliary equipment. With the floor area of less than 4m2, it is easy for placement and saves more production space for users.

2.Control System

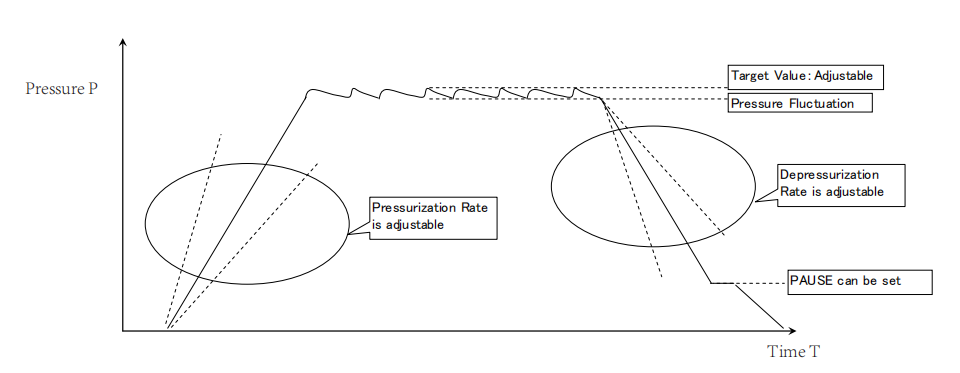

Control system: Adopt the Omron PLC control modules, with the servo system, to achieve the accurate control of the whole process of pressure rise / relief. 1. Adopt the 10in. full-color touch screen of OMRON, and the system will make an immediate response after your figures touch the button on the screen, which is more in line with the operation habits of perators. 2. Friendly human-computer interface, easy to set parameters and check operation conditions. The pressing process curve can be directly viewed in the interface, or the corresponding pressing data can be exported to the PC by USB flash disk for viewing and storage. 3. The membrane switch is attached to the surface of the control cabinet, and its graphical design with lights makes it easy to be understood. 4. The core oil pump generator system adopts excellent servo pump and supporting control motor to accurately control the whole process of pressure rise / relief, ensure the quiet and smooth operation under lower energy consumption than traditional oil pump generator system. The process parameters can be set as follows:

3.Security

To ensure the safety production of the pressing machine, there are multiple security protection settings in the pressing machine.

1. Manual pressure relief valve. In case of any emergency or failure, open the valve manually to enable the pressure relief protection, and the pressure can be increased again after closing it.

2. Pressure sensor and electrical apparatus control system. When the working pressure exceeds the preset pressure value, the electrical apparatus control system will automatically stop the operation of supercharging system and operate the depressurized system to conduct the pressure relief protection.

3. The control cabinet is equipped with a shutdown button, which is used to stop the operation of the pressing machine at any working stage after pressing this button.

4. Interlock of electrical apparatus control procedures. When the pressing machine operates in strict accordance with the working procedures, if the previous procedure is not completed or with failures, the pressing machine cannot proceed to the next procedure, and will send operation failure signal. Only the failure is eliminated, can the pressing machine continue to the next procedure.

4. Parameters Table

Model |

DX300-400 |

Useful diameter of high pressure vessel(mm) |

300 |

Useful depth of high pressure vessel(mm) |

400 |

Maximum working pressure (MPa) |

200/250/300 |

Heating function |

Can be heated to 90 degrees Celsius according to customer needs |

Installed power (Kw) |

17.5 |

Feeding method |

Automatic picking |

Buck-boost rate |

Can be precisely set in sections |

Working medium |

Oil or water-based rust inhibitor |

HMI |

Full color touch screen |

Record data export interface |

USB |

Drive method |

Hydraulic drive |

Cooling method |

Water cooling |

Dimensions (mm) |

Not more than 1800 X 2000 X 2650 |

Weight(t) |

9 |

NdFeB production line

NdFeB production line Vacuum Induction Melting Furnace

Vacuum Induction Melting Furnace